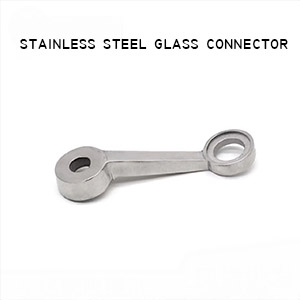

160mm Center-to-Center 2-Way 180 Degree Glass Spider Fitting (I-Shape)

Heavy duty 2-way 180-degree spider fitting with 160mm center-to-center hole distance. I-Shape straight design for connecting two glass panels. Investment cast Stainless Steel 304/316. Ideal for vertical curtain wall joints.

Product Overview

Achieve seamless linearity in your glass facade projects with our 160mm Center-to-Center 2-Way 180 Degree Spider Fitting. Also known as an "I-Shape" or "Straight" fitting, this hardware is engineered to connect two glass panels side-by-side or top-to-bottom in a straight line.

Unlike standard V-shape (90-degree) fittings used at corners, this 180-degree connector is the workhorse for long, continuous spans of glass curtain walls. Manufactured by Stainless Steel Hardwares using precision investment casting, this fitting features a specific 160mm hole-to-hole dimension, making it a compact yet heavy-duty solution for modern architectural glazing.

Technical Specifications

Product Name: 2-Way 180-Degree Glass Spider Fitting

Model Style: I-Shape / Straight Connector

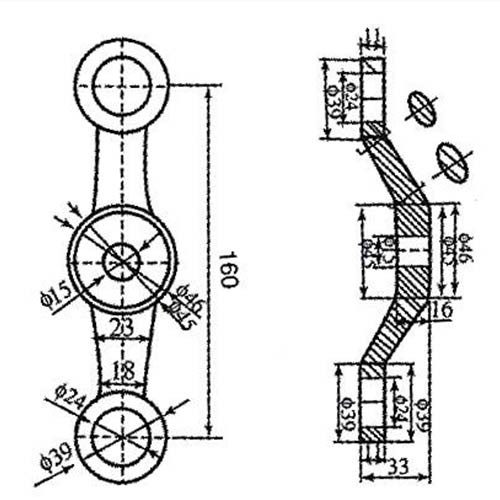

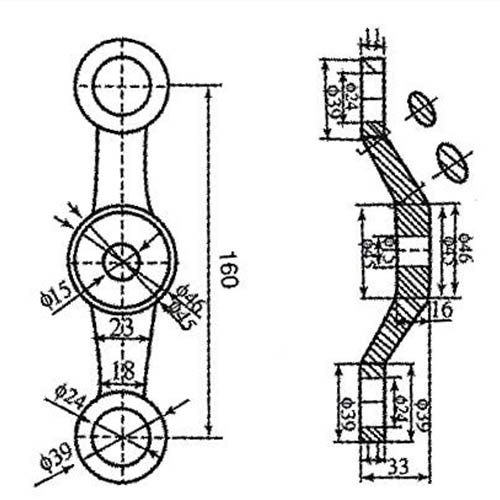

Dimensions: 160mm Center-to-Center (Distance between the two glass mounting holes).

Material Grade:

AISI 304: For standard exterior or interior architectural applications.

AISI 316: Recommended for coastal, marine, or high-humidity environments.

Glass Compatibility: Supports 10mm - 25mm Toughened Glass (Requires matching [Routels]).

Surface Finish: High-grade Satin Brushed (SSS) or Mirror Polished (PSS).

Load Rating: Heavy Duty classification for structural glass walls.

Installation: Welds or bolts to the supporting steel beam via the central base.

Why Choose the 160mm 180-Degree Fitting?

1. Precision "I-Shape" Geometry

The 180-degree configuration is critical for creating flat surfaces.

Vertical Joints: Connects two glass panels vertically along a steel column.

Glass Fin Connection: Often used to connect glass fins (stabilizers) where a straight, robust connection is required.

The linear design offers a minimalist aesthetic, reducing visual clutter on the facade while providing maximum structural support.

2. The 160mm Advantage (Compact & Strong)

This specific model features a 160mm distance between the two routel centers. This is a specific engineering choice that offers a tighter, more rigid connection than wider spread arms. It reduces the leverage on the glass hole, minimizing stress points, while still providing ample clearance for the silicone sealant joint between the glass panels.

3. Investment Cast Durability

We do not use sand casting. Our 2-way spiders are produced using the Lost Wax Investment Casting process. This ensures:

Uniformity: Every piece has the exact same 160mm dimension, ensuring your glass installation runs straight and true.

Surface Quality: No pits or air bubbles. The steel is dense and polish-ready.

Corrosion Resistance: Made from certified ASTM stainless steel, ensuring your facade remains rust-free for decades.

4. Versatile Surface Options

Mirror Polish: Ideal for high-end retail stores and lobbies where the hardware needs to shine like jewelry.

Satin Finish: Perfect for industrial designs or airports, hiding dust and blending with the matte finish of structural steel columns.

Application Scenarios

Continuous Glass Walls: Connecting panels in a straight horizontal row.

Vertical Mullions: Securing glass panels vertically along the height of a building.

Glass Fins: Joining structural glass beams (fins) which require heavy-duty straight connectors.

Partition Walls: Office dividers where glass panels meet in a straight line without a corner post.

Installation Guidelines

Step 1: Measurement Verification

Before ordering, please confirm your glass fabrication drawings. This spider has a 160mm spacing. Ensure your glass holes are drilled to match this specific distance relative to the steel structure.

Step 2: Selecting the Connector

This spider requires a steel adaptor (connector) to attach to your beam. We offer both [Welding Connectors] (for permanent fixation to steel posts) and [Bolting Connectors] (for adjustable fixation).

Step 3: Glass Routels

Do not forget the routels. For this heavy-duty 160mm spider, we recommend our [Heavy Duty Articulated Routels]. The articulated head allows the glass to flex slightly under wind load without breaking.

Frequently Asked Questions (FAQ)

Q: What is the difference between a 90-degree and a 180-degree 2-way spider?

A: A 90-degree (V-Shape) spider is used at corners of a building to join two panels at a right angle. This 180-degree (I-Shape) spider is used on flat walls to join two panels side-by-side in a straight line.

Q: Does "160mm" refer to the arm length or the hole distance?

A: For this specific product page, "160mm" refers to the Center-to-Center distance between the two mounting holes. This is the most critical dimension for your glass driller. Please check the technical drawing below to confirm.

Q: Can this support double glazing?

A: Yes, the spider body is strong enough for double glazing. However, you must order longer [Insulated Glass Routels] to accommodate the thickness of the double-glazed unit.

Q: Is Grade 304 enough for outdoor use?

A: For most inland cities, Grade 304 is sufficient. However, if your project is within 20km of the sea or in a highly polluted industrial zone, we strongly recommend upgrading to Grade 316 to prevent surface corrosion.

Why Partner with Stainless Steel Hardwares?

Material Guarantee: We use real spectrometers to test every batch of molten steel. No fake material.

Project Support: Not sure if you need the 160mm or 200mm size? Send us your CAD drawings or PDF sketches, and our engineers will recommend the correct fitting for your wind load requirements.

Fast Export: We stock standard castings to ensure quick turnaround times for international orders.

Secure your glass structures with confidence.

Contact our sales team today for the latest price list on the 160mm 2-Way I-Shape Spider Fitting.