Heavy Duty 160mm 4-Way Stainless Steel Glass Spider Fitting for Curtain Wall

Heavy Duty 160mm 4-Way Stainless Steel Glass Spider Fitting for Curtain Wall

Premium 160mm 4-arm glass spider fitting for architectural curtain walls. Made from investment cast Stainless Steel 304/316 with satin or mirror finish. High load capacity for heavy glazing. Contact us for specs.

Product Overview

Upgrade your architectural projects with our Heavy Duty 160mm 4-Way Stainless Steel Glass Spider Fitting. Engineered for strength and visual elegance, this X-shape fitting is the backbone of modern point-fixed glass curtain walls. Designed specifically for large-scale commercial facades, shopping mall atriums, and airport canopies, the 160mm series offers superior load-bearing capacity compared to standard lighter fittings, making it the preferred choice for architects and glaziers worldwide.

At Stainless Steel Hardwares, we understand that safety and durability are non-negotiable. That is why our 160mm 4-way spiders are manufactured using precision Lost Wax Investment Casting, ensuring a flawless surface and consistent internal structure free from porosity.

Detailed Specifications

Product Name: 160mm Series 4-Arm Heavy Duty Spider Fitting

Model Type: 4-Way (X-Shape) Configuration

Material Grade: Available in Stainless Steel AISI 304 (for interior/standard exterior) and AISI 316 (for coastal/marine environments).

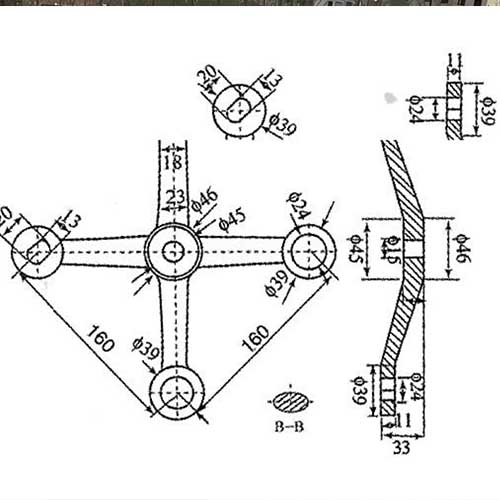

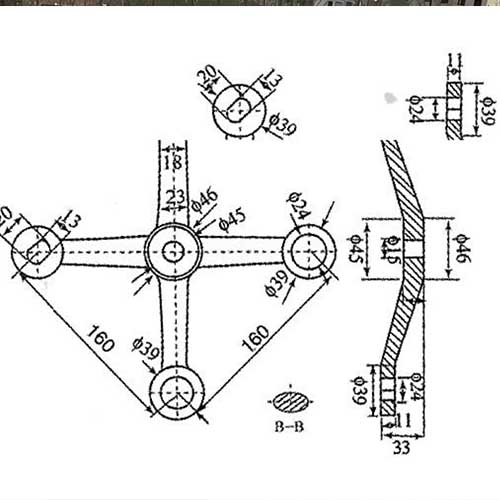

Center-to-Center Dimensions: 160mm x 160mm (Axial distance).

Surface Finish:

Satin Brushed (SSS): For a modern, industrial low-glare look.

Mirror Polished (PSS): For a high-end, reflective luxury appearance.

Glass Compatibility: Optimized for tempered or laminated glass thicknesses ranging from 10mm to 25mm (requires matching [Glass Routels/Connectors]).

Load Capacity: Heavy-duty classification, capable of supporting larger glass panels and resisting high wind loads.

1. Uncompromised Material Quality (SS304 vs. SS316)

The longevity of a glass curtain wall depends entirely on the quality of the steel. We do not cut corners. Our 160mm spider fittings are cast from genuine ASTM-standard stainless steel.

Choose SS316 if your project is located within 20 miles of the ocean or in high-pollution industrial areas. The added molybdenum in Grade 316 provides exceptional resistance to pitting and crevice corrosion.

Choose SS304 for inland projects, interior partitions, or standard climate conditions. It offers excellent strength and rust resistance at a more economical price point.

We provide raw material chemical analysis reports with every shipment to guarantee authenticity.

2. Precision Investment Casting Technology

Unlike cheaper sand-cast alternatives that may hide internal cracks or rough surfaces, our 160mm spiders are produced using the Investment Casting (Lost Wax) process. This manufacturing technique ensures:

Precise dimensional accuracy for easier alignment during installation.

High density and structural strength to withstand the weight of heavy glass panels.

A smooth, defect-free surface that polishes to a perfect shine.

3. Architectural Flexibility and Design

The "X" shape 4-way design is critical for joining four glass panels at a central point. The 160mm arm length provides ample leverage to distribute stress evenly across the glass, reducing the risk of breakage under thermal expansion or wind pressure. The sleek, minimalist design minimizes visual obstruction, allowing for maximum transparency and natural light flow into the building.

4. Easy Adjustability and Installation

Time is money on a construction site. Our spider fittings are designed to work seamlessly with our [Adjustable Glass Routels]. The mounting holes are precision-drilled to allow for minor on-site adjustments, compensating for slight deviations in the main steel structure. This ensures a perfectly flat glass facade every time.

Applications

This 160mm 4-way spider fitting is a versatile component used in various high-end construction scenarios:

Exterior Facades: Main entrances of office buildings, car showrooms, and hotels where a "floating glass" effect is desired.

Glass Canopies & Skylights: Overhead glazing structures requiring robust support against snow loads and wind uplift.

Elevator Shafts: Panoramic glass elevators in shopping malls.

Compatibility: Ensure you select the correct [Glass Connectors/Routels] that match the hole size of this spider fitting. Typically, a heavy-duty spider pairs best with heavy-duty routels.

Cleaning: To maintain the finish, especially for Mirror Polished items, clean the fittings periodically with warm water and a mild detergent. Avoid using abrasive cleaners or steel wool, as these can damage the passivation layer of the stainless steel and lead to surface rust.

Q: Can I use this 160mm spider fitting for a curved glass wall?

A: Yes, spider fittings utilize ball-joint routels which allow for a certain degree of articulation. This makes them suitable for curved or faceted glass designs. Please consult our engineering team for specific angle limitations.

Q: What is the difference between the 150mm, 160mm, and 200mm series?

A: The number refers to the distance between the hole centers or the arm length. The 160mm series is a "Sweet Spot" size—it is stronger than the 150mm light-duty series but more compact and cost-effective than the massive 200mm or 250mm series. It is the industry standard for most medium-to-large commercial projects.

Q: Do you sell the matching accessories?

A: Absolutely. We are a one-stop-shop for curtain wall hardware. You can find matching [1-Way Spiders], [2-Way Spiders], and various welding connectors in our catalog.

Order Your High-Performance Hardware Today

At Stainless Steel Hardwares, we are dedicated to supplying only the best architectural fittings to the global market. Whether you are a local contractor or an international distributor, our 160mm 4-way spider fittings offer the reliability your project demands.

Contact us today for a quote or to request a technical drawing (CAD/PDF).

(Note: Please verify the specific hole-to-hole dimensions with our sales team before ordering to match your glass fabrication drawings exactly.)

Upgrade your architectural projects with our Heavy Duty 160mm 4-Way Stainless Steel Glass Spider Fitting. Engineered for strength and visual elegance, this X-shape fitting is the backbone of modern point-fixed glass curtain walls. Designed specifically for large-scale commercial facades, shopping mall atriums, and airport canopies, the 160mm series offers superior load-bearing capacity compared to standard lighter fittings, making it the preferred choice for architects and glaziers worldwide.

At Stainless Steel Hardwares, we understand that safety and durability are non-negotiable. That is why our 160mm 4-way spiders are manufactured using precision Lost Wax Investment Casting, ensuring a flawless surface and consistent internal structure free from porosity.

Detailed Specifications

Product Name: 160mm Series 4-Arm Heavy Duty Spider Fitting

Model Type: 4-Way (X-Shape) Configuration

Material Grade: Available in Stainless Steel AISI 304 (for interior/standard exterior) and AISI 316 (for coastal/marine environments).

Center-to-Center Dimensions: 160mm x 160mm (Axial distance).

Surface Finish:

Satin Brushed (SSS): For a modern, industrial low-glare look.

Mirror Polished (PSS): For a high-end, reflective luxury appearance.

Glass Compatibility: Optimized for tempered or laminated glass thicknesses ranging from 10mm to 25mm (requires matching [Glass Routels/Connectors]).

Load Capacity: Heavy-duty classification, capable of supporting larger glass panels and resisting high wind loads.

Installation Method: Welded to steel structure or bolted via connector sleeve.

1. Uncompromised Material Quality (SS304 vs. SS316)

The longevity of a glass curtain wall depends entirely on the quality of the steel. We do not cut corners. Our 160mm spider fittings are cast from genuine ASTM-standard stainless steel.

Choose SS316 if your project is located within 20 miles of the ocean or in high-pollution industrial areas. The added molybdenum in Grade 316 provides exceptional resistance to pitting and crevice corrosion.

Choose SS304 for inland projects, interior partitions, or standard climate conditions. It offers excellent strength and rust resistance at a more economical price point.

We provide raw material chemical analysis reports with every shipment to guarantee authenticity.

2. Precision Investment Casting Technology

Unlike cheaper sand-cast alternatives that may hide internal cracks or rough surfaces, our 160mm spiders are produced using the Investment Casting (Lost Wax) process. This manufacturing technique ensures:

Precise dimensional accuracy for easier alignment during installation.

High density and structural strength to withstand the weight of heavy glass panels.

A smooth, defect-free surface that polishes to a perfect shine.

3. Architectural Flexibility and Design

The "X" shape 4-way design is critical for joining four glass panels at a central point. The 160mm arm length provides ample leverage to distribute stress evenly across the glass, reducing the risk of breakage under thermal expansion or wind pressure. The sleek, minimalist design minimizes visual obstruction, allowing for maximum transparency and natural light flow into the building.

4. Easy Adjustability and Installation

Time is money on a construction site. Our spider fittings are designed to work seamlessly with our [Adjustable Glass Routels]. The mounting holes are precision-drilled to allow for minor on-site adjustments, compensating for slight deviations in the main steel structure. This ensures a perfectly flat glass facade every time.

Applications

This 160mm 4-way spider fitting is a versatile component used in various high-end construction scenarios:

Exterior Facades: Main entrances of office buildings, car showrooms, and hotels where a "floating glass" effect is desired.

Glass Canopies & Skylights: Overhead glazing structures requiring robust support against snow loads and wind uplift.

Elevator Shafts: Panoramic glass elevators in shopping malls.

Double-Skin Facades: Energy-efficient building envelopes that use spider fittings to hold the outer glass layer.

Compatibility: Ensure you select the correct [Glass Connectors/Routels] that match the hole size of this spider fitting. Typically, a heavy-duty spider pairs best with heavy-duty routels.

Cleaning: To maintain the finish, especially for Mirror Polished items, clean the fittings periodically with warm water and a mild detergent. Avoid using abrasive cleaners or steel wool, as these can damage the passivation layer of the stainless steel and lead to surface rust.

Inspection: For high-rise applications, we recommend a visual inspection of the fittings and bolts annually to ensure tightness and structural integrity.

Q: Can I use this 160mm spider fitting for a curved glass wall?

A: Yes, spider fittings utilize ball-joint routels which allow for a certain degree of articulation. This makes them suitable for curved or faceted glass designs. Please consult our engineering team for specific angle limitations.

Q: What is the difference between the 150mm, 160mm, and 200mm series?

A: The number refers to the distance between the hole centers or the arm length. The 160mm series is a "Sweet Spot" size—it is stronger than the 150mm light-duty series but more compact and cost-effective than the massive 200mm or 250mm series. It is the industry standard for most medium-to-large commercial projects.

Q: Do you sell the matching accessories?

A: Absolutely. We are a one-stop-shop for curtain wall hardware. You can find matching [1-Way Spiders], [2-Way Spiders], and various welding connectors in our catalog.

Order Your High-Performance Hardware Today

At Stainless Steel Hardwares, we are dedicated to supplying only the best architectural fittings to the global market. Whether you are a local contractor or an international distributor, our 160mm 4-way spider fittings offer the reliability your project demands.

Contact us today for a quote or to request a technical drawing (CAD/PDF).

(Note: Please verify the specific hole-to-hole dimensions with our sales team before ordering to match your glass fabrication drawings exactly.)