150mm Series 4-Way Stainless Steel Spider Fitting - Model RL1501 for Heavy Duty Glass Facades

150mm Series 4-Way Stainless Steel Spider Fitting - Model RL1501 for Heavy Duty Glass Facades

RL1501 150mm stainless steel 4 arm spider fittings for glass canopy, skylight, facade and glass elevator. China spider fittings manufacturer and factory, 304 or 316 material, wholesale and custom service for Africa, Middle East, Southeast Asia projects.

Product Name

RL1501 150mm Stainless Steel 4 Arm Spider Fittings For Glass

Category

Architectural glass hardware

Point fixed glass fittings

Stainless steel glass spider fittings

Product Overview

RL1501 150mm stainless steel 4 arm spider fitting is a classic four way glass spider designed for point fixed glass facade and canopy systems. It connects glass panels to steel structures or tension rod systems and provides four point support around each glass node, which improves safety and stability of the whole glass assembly.

This model belongs to the 150 series spider fittings with a 150 by 150 millimeter center distance. It is widely used in commercial plazas, shopping malls, office building entrances, glass canopies, glass skylights, glass elevators and panoramic corridors. In the international market, this type of product is commonly called spider fittings, glass spider fittings, 4 arm spider fitting or four way glass spider.

As a professional manufacturer, factory and wholesale supplier of spider fittings in China, we supply RL1501 four arm spider fittings in stainless steel 304 and 316, with satin or mirror finish. We support custom design according to project drawings and export regularly to Africa, the Middle East, Southeast Asia and many other regions.

Key Features And Advantages

Four arm design with balanced loading

RL1501 adopts a symmetrical four arm layout with a 150 x 150 mm grid. Each arm holds one glass fixing bolt and transfers loads from the glass to the main structure. Compared with two arm fittings, a 4 arm spider can distribute wind load, dead load and live load to four different points, which improves overall safety of the point fixed glass system.

Integrated precision casting body

The main body of the spider fitting is produced by precision investment casting. The four arms and central hub are cast as one piece, which avoids weak points at welded joints and offers higher strength and longer service life. The smooth curvature between arms and center hub also provides good stress distribution and an elegant architectural appearance.

High quality stainless steel

Standard material is stainless steel 304, which is suitable for most indoor and outdoor applications. For coastal projects, chemical plants or other aggressive environments, we recommend stainless steel 316 or 316L to achieve better corrosion resistance. All matching bolts, nuts, sleeves and washers can be supplied in the same material, so the complete glass spider fittings system performs consistently.

Attractive surface finish

Both satin (brushed) and mirror polished finishes are available. Satin finish is widely used in commercial buildings because of its low maintenance requirement and modern look. Mirror finish shows a strong metallic gloss and is often selected for hotel lobbies, high grade office buildings and observation elevators where visual impact is important.

Flexible connection to different structures

RL1501 four arm spider fittings can be connected to steel posts, H beams, round tubes, trusses, reinforced concrete structures with embedded plates, or tension rod and cable systems. With the help of different adapters and brackets, the same spider model can be used on flat facades, corners, slopes and curved surfaces.

Factory direct supply and custom service

We are not only a supplier but also a spider fittings manufacturer and factory. Besides standard RL1501 150 mm four arm spider fittings, we can produce customized versions with different center distances, hole diameters, arm shapes or special angles. OEM and ODM orders are welcome. For distributors and project contractors, we offer competitive wholesale prices, stable lead time and professional technical support.

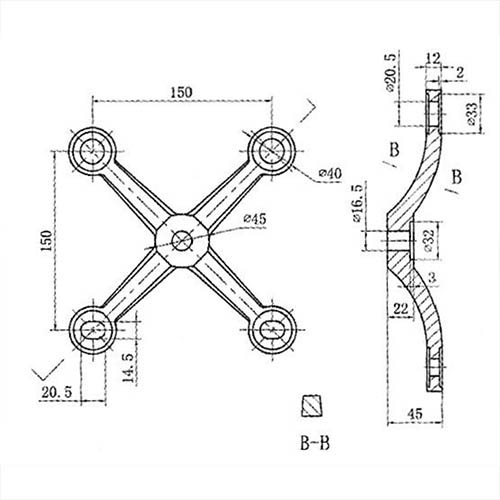

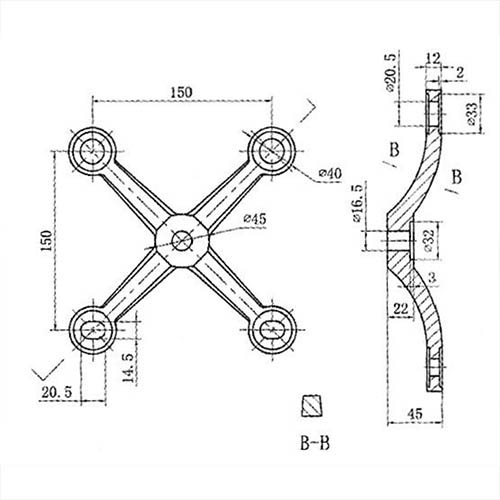

Technical Data

Model: RL1501

Type: 4 arm spider fitting, four way glass spider

Center distance: 150 mm x 150 mm

Center hub diameter: about 45 mm

Arm head diameter: about 40 mm

Glass fixing hole matching diameter: about 16.5 mm

Arm thickness: around 14.5–20.5 mm depending on the position

Material: stainless steel 304, stainless steel 316 or 316L

Surface finish: satin (brushed) or mirror polished

Suitable glass: tempered glass, laminated glass, insulating glass with drilled holes

Typical glass thickness: 10–25 mm depending on design

Application: glass canopy, glass skylight, glass curtain wall, glass elevator shaft, glass corridor, glass balustrade and handrail

Typical Applications

Commercial plaza glass canopy

At the main entrance of shopping malls and commercial plazas, RL1501 spider fittings are used to support glass canopies together with tension rods or steel beams. The stainless steel spider fittings ensure a safe connection between glass and structure while keeping the canopy visually light and transparent.

Skylights and roof glazing

Large skylights on office buildings, airports, railway stations and exhibition centers often use point fixed glass systems. RL1501 4 arm spider fittings arranged in a 150 x 150 grid distribute the weight of glass panels and resist wind load. With proper design of slopes and gutters, the system can provide excellent daylighting and reliable waterproof performance.

Glass curtain wall and facade

When used on glass facades, spider fittings help create a frameless appearance with minimal visible hardware. RL1501 is suitable for medium size facades with regular grid, and can be combined with vertical steel posts, cable walls or trussed structures. The clean lines and small visible area of the four arm spider are ideal for modern architecture.

Glass elevator and observation shaft

For glass observation elevators in shopping malls, hotels and office buildings, RL1501 stainless steel spider fittings can be used around the shaft to fix vertical glass panels. The fittings provide sufficient structural strength while keeping the view open, giving passengers a panoramic experience.

Pedestrian bridges and glass corridors

In glass corridors, sky bridges and viewing platforms, point fixed glass with spider fittings is widely used. RL1501 150mm four arm spider can connect glass side walls, roof panels or balustrades to the supporting steel frame, offering transparency and modern aesthetic at the same time.

Installation Guidelines And Notes

Design stage

A qualified structural engineer should select appropriate glass thickness, spider fitting model and fixing details according to local codes, design wind pressure, building height and span. RL1501 4 arm spider fitting is suitable for many projects, but some large span or high rise facades may require other types or additional reinforcement.

Installation steps (summary)

Check all components including spiders, routels, bolts and gaskets. Make sure surfaces are clean and free from damage.

Fix the RL1501 spider fittings on the steel structure or adapter plates according to drawings. Align the center lines and angles carefully.

Lift the pre drilled glass panel into position, insert the routel bolts through the glass holes and connect them to the spider arms.

Tighten all bolts evenly with a torque wrench. Do not over tighten to avoid excessive local stress on the glass.

After installing all glass panels, check joint gaps, sealant condition and alignment of the whole facade or canopy.

Important notes

Glass edges and holes must be processed by qualified glass factories and comply with relevant standards.

All contact surfaces between glass and metal should be separated by appropriate nylon or rubber gaskets.

In coastal or industrial environments, using 316 stainless steel spider fittings is strongly recommended.

Periodic inspection should be carried out. If any bolts are loose or any component shows serious corrosion or deformation, replace them immediately.

Global Market And Regions

Our spider fittings, including RL1501 four arm spider fitting, have been supplied to many countries and regions. In Africa, customers from Algeria, Angola, Nigeria, Ghana, South Africa, Kenya, Tanzania and Ethiopia often use our glass spider fittings in shopping malls, office buildings and hotels.

In the Middle East, we cooperate with contractors in the United Arab Emirates, Saudi Arabia, Qatar, Kuwait and Oman for glass canopy and facade projects. In Asia, our products are exported to Vietnam, Indonesia, Malaysia, Thailand, the Philippines, India and Pakistan. Many customers search for us by phrases such as glass spider fittings supplier, spider fitting manufacturer china, spider fittings wholesale or custom spider fittings.

By optimizing our product pages for common search habits in different countries, we help overseas buyers easily find the right spider glazing hardware for their projects.

Why Choose Our RL1501 Spider Fittings

Professional manufacturer and factory with years of experience in stainless steel glass hardware

Full range of spider fittings, routels, adapters and tension rod systems

High quality stainless steel 304 and 316 with strict quality control

Flexible OEM, ODM and custom design service based on project drawings

Competitive wholesale price and stable delivery time for distributors and contractors

Q1. What glass thickness can be used with RL1501 4 arm spider fittings

A1. In most projects RL1501 can work with tempered or laminated glass from 10 mm up to 25 mm thick. The final selection of glass thickness should be made by the structural engineer according to span, wind load and safety requirements.

Q2. How to choose between stainless steel 304 and 316 for spider fittings

A2. For indoor applications and normal urban environments, stainless steel 304 is usually sufficient. For coastal areas, high humidity zones, chemical or industrial environments, stainless steel 316 or 316L is recommended because of its better corrosion resistance and longer service life.

Q3. Can you provide matching routels and other accessories

A3. Yes. We can supply complete sets of point fixed glass fittings including RL1501 four arm spider fittings, routels, bolts, sleeves, spacers, tension rods and other stainless steel hardware. All parts are compatible and made from the same material grade.

Q4. Do you accept small orders or only wholesale

A4. We mainly focus on wholesale orders for distributors, engineering companies and facade contractors, but we also accept small trial orders for new customers or small projects. Please contact us with your quantity and project details so that we can quote accordingly.

Q5. Can you ship spider fittings to Africa or the Middle East

A5. Yes. We already export glass spider fittings to Algeria, Angola, Nigeria, South Africa, the United Arab Emirates, Saudi Arabia and many other countries. We can arrange sea or air shipment from Chinese ports and provide suitable export packaging for long distance transportation.

Contact Information

Email: stainless.steels.hardware@gmail.com

Website: www.stainlesssteelhardwares.com

Tel: +86-180-61818518

RL1501 150mm Stainless Steel 4 Arm Spider Fittings For Glass

Category

Architectural glass hardware

Point fixed glass fittings

Stainless steel glass spider fittings

Product Overview

RL1501 150mm stainless steel 4 arm spider fitting is a classic four way glass spider designed for point fixed glass facade and canopy systems. It connects glass panels to steel structures or tension rod systems and provides four point support around each glass node, which improves safety and stability of the whole glass assembly.

This model belongs to the 150 series spider fittings with a 150 by 150 millimeter center distance. It is widely used in commercial plazas, shopping malls, office building entrances, glass canopies, glass skylights, glass elevators and panoramic corridors. In the international market, this type of product is commonly called spider fittings, glass spider fittings, 4 arm spider fitting or four way glass spider.

As a professional manufacturer, factory and wholesale supplier of spider fittings in China, we supply RL1501 four arm spider fittings in stainless steel 304 and 316, with satin or mirror finish. We support custom design according to project drawings and export regularly to Africa, the Middle East, Southeast Asia and many other regions.

Key Features And Advantages

Four arm design with balanced loading

RL1501 adopts a symmetrical four arm layout with a 150 x 150 mm grid. Each arm holds one glass fixing bolt and transfers loads from the glass to the main structure. Compared with two arm fittings, a 4 arm spider can distribute wind load, dead load and live load to four different points, which improves overall safety of the point fixed glass system.

Integrated precision casting body

The main body of the spider fitting is produced by precision investment casting. The four arms and central hub are cast as one piece, which avoids weak points at welded joints and offers higher strength and longer service life. The smooth curvature between arms and center hub also provides good stress distribution and an elegant architectural appearance.

High quality stainless steel

Standard material is stainless steel 304, which is suitable for most indoor and outdoor applications. For coastal projects, chemical plants or other aggressive environments, we recommend stainless steel 316 or 316L to achieve better corrosion resistance. All matching bolts, nuts, sleeves and washers can be supplied in the same material, so the complete glass spider fittings system performs consistently.

Attractive surface finish

Both satin (brushed) and mirror polished finishes are available. Satin finish is widely used in commercial buildings because of its low maintenance requirement and modern look. Mirror finish shows a strong metallic gloss and is often selected for hotel lobbies, high grade office buildings and observation elevators where visual impact is important.

Flexible connection to different structures

RL1501 four arm spider fittings can be connected to steel posts, H beams, round tubes, trusses, reinforced concrete structures with embedded plates, or tension rod and cable systems. With the help of different adapters and brackets, the same spider model can be used on flat facades, corners, slopes and curved surfaces.

Factory direct supply and custom service

We are not only a supplier but also a spider fittings manufacturer and factory. Besides standard RL1501 150 mm four arm spider fittings, we can produce customized versions with different center distances, hole diameters, arm shapes or special angles. OEM and ODM orders are welcome. For distributors and project contractors, we offer competitive wholesale prices, stable lead time and professional technical support.

Technical Data

Model: RL1501

Type: 4 arm spider fitting, four way glass spider

Center distance: 150 mm x 150 mm

Center hub diameter: about 45 mm

Arm head diameter: about 40 mm

Glass fixing hole matching diameter: about 16.5 mm

Arm thickness: around 14.5–20.5 mm depending on the position

Material: stainless steel 304, stainless steel 316 or 316L

Surface finish: satin (brushed) or mirror polished

Suitable glass: tempered glass, laminated glass, insulating glass with drilled holes

Typical glass thickness: 10–25 mm depending on design

Application: glass canopy, glass skylight, glass curtain wall, glass elevator shaft, glass corridor, glass balustrade and handrail

Typical Applications

Commercial plaza glass canopy

At the main entrance of shopping malls and commercial plazas, RL1501 spider fittings are used to support glass canopies together with tension rods or steel beams. The stainless steel spider fittings ensure a safe connection between glass and structure while keeping the canopy visually light and transparent.

Skylights and roof glazing

Large skylights on office buildings, airports, railway stations and exhibition centers often use point fixed glass systems. RL1501 4 arm spider fittings arranged in a 150 x 150 grid distribute the weight of glass panels and resist wind load. With proper design of slopes and gutters, the system can provide excellent daylighting and reliable waterproof performance.

Glass curtain wall and facade

When used on glass facades, spider fittings help create a frameless appearance with minimal visible hardware. RL1501 is suitable for medium size facades with regular grid, and can be combined with vertical steel posts, cable walls or trussed structures. The clean lines and small visible area of the four arm spider are ideal for modern architecture.

Glass elevator and observation shaft

For glass observation elevators in shopping malls, hotels and office buildings, RL1501 stainless steel spider fittings can be used around the shaft to fix vertical glass panels. The fittings provide sufficient structural strength while keeping the view open, giving passengers a panoramic experience.

Pedestrian bridges and glass corridors

In glass corridors, sky bridges and viewing platforms, point fixed glass with spider fittings is widely used. RL1501 150mm four arm spider can connect glass side walls, roof panels or balustrades to the supporting steel frame, offering transparency and modern aesthetic at the same time.

Installation Guidelines And Notes

Design stage

A qualified structural engineer should select appropriate glass thickness, spider fitting model and fixing details according to local codes, design wind pressure, building height and span. RL1501 4 arm spider fitting is suitable for many projects, but some large span or high rise facades may require other types or additional reinforcement.

Installation steps (summary)

Check all components including spiders, routels, bolts and gaskets. Make sure surfaces are clean and free from damage.

Fix the RL1501 spider fittings on the steel structure or adapter plates according to drawings. Align the center lines and angles carefully.

Lift the pre drilled glass panel into position, insert the routel bolts through the glass holes and connect them to the spider arms.

Tighten all bolts evenly with a torque wrench. Do not over tighten to avoid excessive local stress on the glass.

After installing all glass panels, check joint gaps, sealant condition and alignment of the whole facade or canopy.

Important notes

Glass edges and holes must be processed by qualified glass factories and comply with relevant standards.

All contact surfaces between glass and metal should be separated by appropriate nylon or rubber gaskets.

In coastal or industrial environments, using 316 stainless steel spider fittings is strongly recommended.

Periodic inspection should be carried out. If any bolts are loose or any component shows serious corrosion or deformation, replace them immediately.

Global Market And Regions

Our spider fittings, including RL1501 four arm spider fitting, have been supplied to many countries and regions. In Africa, customers from Algeria, Angola, Nigeria, Ghana, South Africa, Kenya, Tanzania and Ethiopia often use our glass spider fittings in shopping malls, office buildings and hotels.

In the Middle East, we cooperate with contractors in the United Arab Emirates, Saudi Arabia, Qatar, Kuwait and Oman for glass canopy and facade projects. In Asia, our products are exported to Vietnam, Indonesia, Malaysia, Thailand, the Philippines, India and Pakistan. Many customers search for us by phrases such as glass spider fittings supplier, spider fitting manufacturer china, spider fittings wholesale or custom spider fittings.

By optimizing our product pages for common search habits in different countries, we help overseas buyers easily find the right spider glazing hardware for their projects.

Why Choose Our RL1501 Spider Fittings

Professional manufacturer and factory with years of experience in stainless steel glass hardware

Full range of spider fittings, routels, adapters and tension rod systems

High quality stainless steel 304 and 316 with strict quality control

Flexible OEM, ODM and custom design service based on project drawings

Competitive wholesale price and stable delivery time for distributors and contractors

Technical support for design, selection and installation of point fixed glass systems

Q1. What glass thickness can be used with RL1501 4 arm spider fittings

A1. In most projects RL1501 can work with tempered or laminated glass from 10 mm up to 25 mm thick. The final selection of glass thickness should be made by the structural engineer according to span, wind load and safety requirements.

Q2. How to choose between stainless steel 304 and 316 for spider fittings

A2. For indoor applications and normal urban environments, stainless steel 304 is usually sufficient. For coastal areas, high humidity zones, chemical or industrial environments, stainless steel 316 or 316L is recommended because of its better corrosion resistance and longer service life.

Q3. Can you provide matching routels and other accessories

A3. Yes. We can supply complete sets of point fixed glass fittings including RL1501 four arm spider fittings, routels, bolts, sleeves, spacers, tension rods and other stainless steel hardware. All parts are compatible and made from the same material grade.

Q4. Do you accept small orders or only wholesale

A4. We mainly focus on wholesale orders for distributors, engineering companies and facade contractors, but we also accept small trial orders for new customers or small projects. Please contact us with your quantity and project details so that we can quote accordingly.

Q5. Can you ship spider fittings to Africa or the Middle East

A5. Yes. We already export glass spider fittings to Algeria, Angola, Nigeria, South Africa, the United Arab Emirates, Saudi Arabia and many other countries. We can arrange sea or air shipment from Chinese ports and provide suitable export packaging for long distance transportation.

Contact Information

Email: stainless.steels.hardware@gmail.com

Website: www.stainlesssteelhardwares.com

Tel: +86-180-61818518

tag:

RL1501 spider fitting

150mm 4 arm spider fitting

stainless steel glass spider fittings

four way glass spider

glass canopy spider hardware

glass skylight fittings

curtain wall spider fitting

point fixed glass fittings

spider glazing hardware manufacturer

spider fittings factory

spider fittings wholesale

custom spider fittings