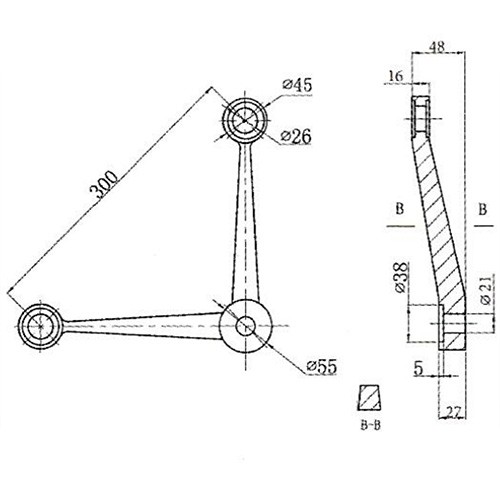

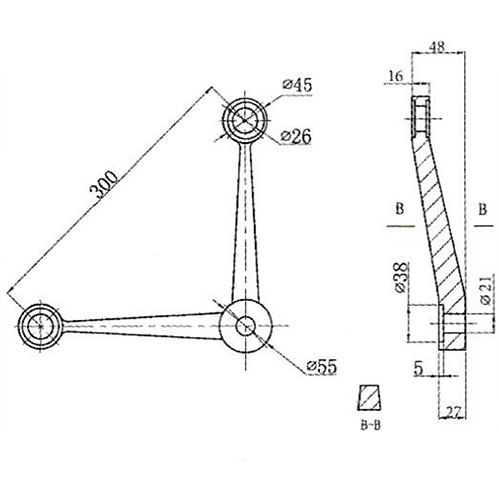

Stainless Steel Double-Arm Spider Fitting 300N4 | 90° Glass Curtain Wall Connector

300N4 double-arm spider fitting with 300mm center distance and 90° angle, made of 304/316 stainless steel, ideal for corner glass wall installations.

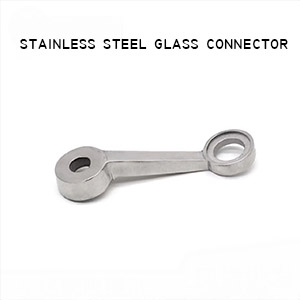

The 300N4 stainless steel spider fitting is a double-arm structural connector specially designed for glass curtain wall corners. With a 90-degree angle between arms and a 300mm center-to-center distance, it is ideal for corner joints or perpendicular glass panel installations.

Made of high-grade 304 or 316 stainless steel, this fitting provides excellent strength and corrosion resistance. It supports various surface finishes such as brushed, mirror polished, or titanium-coated, making it suitable for both functional and architectural needs.

Key Features:

-

300mm center distance fits most standard glass hole positions

-

90° fixed angle perfect for L-shaped or corner curtain wall structures

-

Supports custom finishes and optional matching parts

-

Can be used with routels, tension rods, and adapter fittings

Installation Method (Recommended):

-

Preparation: Ensure the steel frame, glass panels, and hole positions are accurately measured and aligned. Welding of adapter parts on the steel beam should be completed.

-

Fix the Spider Fitting: Attach the 300N4 spider fitting securely to the adapter connector. Make sure the arms form a true 90° angle and all bolts are tightened.

-

Install the Routel: Mount the stainless steel routel onto the pre-drilled holes on the glass panel. Don’t forget to insert spacers to prevent direct contact between metal and glass.

-

Position the Glass Panel: Hang the glass onto the spider arms. Connect the routels to the spider fitting loosely at first to allow position adjustment.

-

Final Adjustment and Tightening: Once all panels are aligned, tighten the bolts fully and check for structural stability and even stress distribution.

The 300N4 model is commonly used in commercial building facades, showroom entries, hotel lobbies, and atrium corners, especially where sleek corner glass designs are desired.

Our factory provides complete support, including CAD drawings, custom sizing, compatible fittings (spider routels, tension rods, base anchors), and engineering consultation.

Contact us today for technical details or tailored project solutions. We are ready to support your glass system integration with professional-grade spider fittings and accessories.