Stainless Steel Spider Fittings: Curtain Walls vs. Canopies | Facade Solutions Singapore

In the realm of modern architectural design—particularly in dynamic Southeast Asian cities like Singapore and Kuala Lumpur—architects are in a constant pursuit of the perfect balance between "light" and "structure." The evolution of the Point-fixed Glass System has revolutionized how we perceive building envelopes. Yet, the core of this sophisticated system lies in a component that is small in size but immense in responsibility: the Stainless Steel Spider Fitting.

Recently, on our YouTube Channel, we released a video case study that visually demonstrates how the exact same high-quality spider fitting serves two completely different structural purposes.

Today, expanding on that video, we will dive deep into the technical applications of stainless steel spider fittings in both commercial glass curtain walls and residential underground garage canopies, and analyze why high-grade stainless steel is the only viable choice for the tropical, coastal climate of Singapore.

Scenario 1: The Commercial Glass Curtain Wall YOUTUBE

In the opening sequence of our video, we showcase the spider fitting applied to a high-rise building façade. This is not just a mechanical connection; it is a feat of structural engineering.

1. Maximizing Transparency in Urban Density

In Singapore’s dense Central Business District (CBD), traditional framed curtain walls can feel heavy and obstructive. By utilizing our Stainless Steel Spider Fittings paired with Articulated Routels, architects can minimize the visual obstruction of the supporting structure.

This "invisible" support system allows natural light to flood the interior unhindered. For Green Mark certified buildings in Singapore, this increased natural lighting significantly reduces the need for artificial illumination during the day, contributing to energy efficiency goals.

2. Dynamic Load Absorption & Typhoon Resistance

High-rise buildings face significant wind loads. A rigid connection in a glass façade can be disastrous. Our spider fittings are designed with a unique "joint" flexibility.

When strong monsoon winds buffer the glass surface, the spider fitting—working in tandem with the routel—allows for micro-movements. This absorbs the deflection and stress of the glass panel, preventing breakage. The 4-way spider configuration shown in the video is specifically engineered to distribute the weight and wind load of large glass panels evenly across four points, ensuring safety during tropical storms.

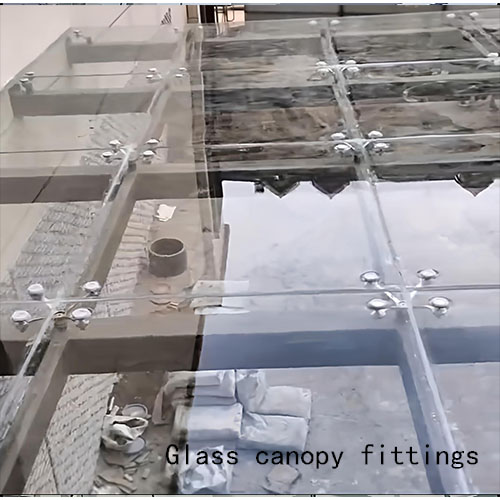

Scenario 2: The Underground Garage Entrance Canopy On Youtube

The second half of our video shifts to a more grounded, functional application: the entrance ramp of an underground parking garage. Here, the same spider system is employed, but the engineering demands shift.

1. Protection Against Tropical Downpours

The climate in Singapore and Malaysia is characterized by sudden, heavy rainfall. A glass canopy at a garage entrance is not merely decorative; it is a shield.

In this application, the spider fittings connect the structural steel skeleton to the tempered laminated glass. Unlike the vertical load of a curtain wall, canopy fittings must withstand vertical gravity loads (the weight of the glass) and, crucially, Wind Uplift (Negative Pressure). During a storm, wind can attempt to "lift" the glass off the structure. Our precision-cast fittings lock the glass securely in place, preventing detachment even under severe negative pressure.

2. Illuminating Subterranean Spaces

Underground entrances can often feel dark and claustrophobic. By replacing heavy concrete or aluminum covers with a point-fixed glass canopy, natural light is channeled directly into the tunnel entrance. The reflection of the stainless steel hardware against the glass adds a modern, premium aesthetic that elevates the property's value while improving visibility for drivers.

The Singapore Factor: Why SS316 is Non-Negotiable

We often receive inquiries from global clients asking about material grades. For projects in Singapore, Indonesia, Thailand, and Vietnam, we have one strict recommendation: Use SUS316 Grade Stainless Steel.

1. Combating Salt Spray Corrosion

Singapore is an island nation; the air carries a high salt content (salinity). Standard carbon steel or even lower-grade 304 stainless steel is prone to "tea staining" (superficial rust) when exposed to coastal breezes over time.

Our spider fittings are cast from high-purity 316 Stainless Steel. This alloy contains Molybdenum (Mo), which drastically enhances its resistance to pitting and chloride corrosion. This ensures that the hardware remains structurally sound and aesthetically pristine for decades, even in seafront properties like those in Sentosa or Marina Bay.

2. Resilience in High Humidity

The combination of high heat and high humidity accelerates oxidation. Our products undergo rigorous surface treatments—either Mirror Polished (PSS) or Satin Brushed (SSS). This polishing process not only creates a stunning visual finish but also seals the surface, reducing the microscopic crevices where moisture and contaminants can accumulate.

Technical Deep Dive: From Casting to Installation

As a premier manufacturer, StainlessSteelHardwares.com provides more than just parts; we provide structural confidence.

Investment Casting Process (Lost Wax): Every spider fitting we produce utilizes the lost wax casting method. This ensures micron-level dimensional accuracy, eliminating internal air pockets or sand holes that could compromise structural integrity.

Versatile Configurations: As seen in the video, our system is adaptable. Whether connecting to a vertical I-beam, a round steel pipe, or a concrete wall, we offer the necessary adaptors.

K-Shape Spiders: For standard grid curtain walls.

X-Shape Spiders: For heavy-duty spans.

Fin Spiders: For connecting to glass fins rather than steel.

Conclusion: Choosing a Partner for Your Southeast Asian Projects

Our video demo (Watch on YouTube) shows just the tip of the iceberg regarding what our hardware can achieve. From the skyline to the subway line, our stainless steel spider fittings are the silent strength behind the glass.

Are you ready to optimize your next architectural project?

Visit our full catalog at www.stainlesssteelhardwares.com or contact our export team today to discuss custom solutions tailored for the Southeast Asian market.