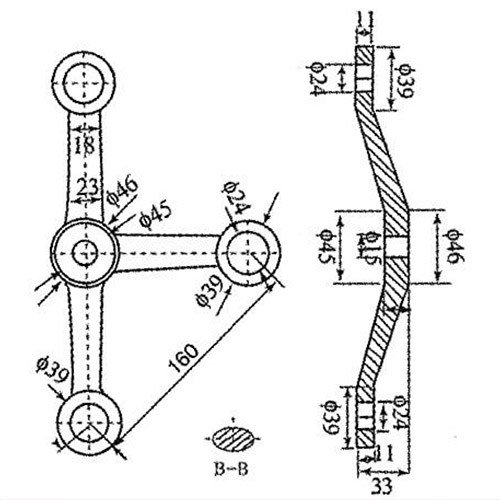

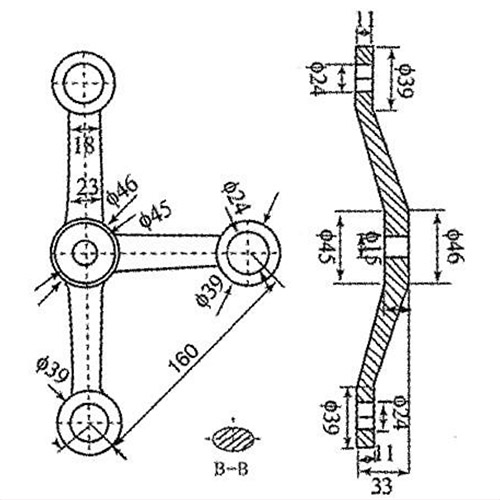

160mm 3-Way Stainless Steel Glass Spider Fitting (T-Shape) for Curtain Wall Edges

Heavy duty 160mm 3-way spider fitting with T-shape design. Ideal for curtain wall edges and corners. Manufactured from investment cast Stainless Steel 304/316. High load bearing capacity. Factory direct pricing.

Product Overview

Secure the perimeter of your glass structures with our 160mm 3-Way Stainless Steel Glass Spider Fitting. While 4-way fittings handle the central loads of a facade, the 3-way (T-Shape) fitting is the critical component designed for the edges, bottom rows, and top sections of point-fixed glass curtain walls.

Engineered by Stainless Steel Hardwares for heavy-duty applications, this 160mm series fitting ensures stability where the glass grid terminates. Whether you are constructing a massive shopping mall entrance or a boutique storefront, our investment-cast spider fittings offer the perfect balance of structural safety and architectural beauty.

Detailed Specifications

Product Name: 160mm Series 3-Arm Spider Fitting

Configuration: 3-Way / T-Shape (Two horizontal arms, one vertical arm)

Material Options:

AISI 304: Standard grade for interior or non-coastal exterior use.

AISI 316:Marine grade with Molybdenum for superior corrosion resistance in coastal/high-salinity areas.

Arm Length / Size: 160mm (Center to hole distance) – Heavy Duty Series.

Surface Finish: Satin Brushed (SSS) or Mirror Polished (PSS).

Glass Thickness: Supports 10mm to 25mm tempered/laminated glass (dependent on [Routel] selection).

Manufacturing Process: Lost Wax Investment Casting (Solicas).

Mounting: Welds or bolts to the steel fin/structure via the central base.

Key Features & Benefits

1. Optimized for Facade Edges (The T-Shape Design)

The 3-way spider is specifically engineered for the perimeter of your glass wall.

Vertical Edges: Connects two vertical glass panels and secures them to the side structure.

Horizontal Edges: Used at the very top or bottom of a curtain wall to secure the final row of glass panels.

This specific "T" configuration ensures that your load distribution remains balanced even at the termination points of the building grid.

2. Heavy Duty 160mm Construction

Unlike smaller 100mm or 120mm fittings which are suitable for canopies or small partitions, the 160mm series is a true heavy-weight performer. The longer arm length and thicker casting body allow it to support larger glass spans and withstand higher wind pressures (Wind Load), making it the standard choice for main building facades.

3. Premium Stainless Steel (Spectrometer Tested)

We guarantee the chemical composition of our steel.

Rust Prevention: Our Grade 316 stainless steel prevents "tea staining" and pitting, even in harsh environments.

Strength: The casting process ensures a solid internal grain structure, preventing mechanical failure under stress.

We provide Mill Test Certificates (MTC) with every order.

4. Flawless Finish

Architectural hardware is as much about looks as it is about function. Our fittings undergo a rigorous polishing process.

Mirror Polish: Creates a chrome-like, reflective surface that disappears into the glass reflection.

Satin Brush: Provides a sophisticated, matte texture that hides fingerprints and matches modern steel beams.

Installation & Compatibility

Matching the System:

A spider fitting is only one part of the system. For a complete installation, this 3-way spider must be paired with:

[Glass Routels / Connectors]: The bolts that go through the glass. Ensure you choose the correct head type (countersunk or flat head) to match your glass fabrication.

[Connector Sleeve / Adaptor]: To connect the spider base to your steel column or beam.

Adjustability:

Our 160mm spiders feature oval-shaped mounting holes on the arms. This is a critical feature for installers, allowing for +/- adjustment during installation. If the steel structure behind the glass is not 100% perfectly aligned, these adjustable arms allow the glazier to shift the routel position slightly to ensure the glass panels line up perfectly without stress.

Application Scenarios

Commercial Curtain Walls: Specifically for the side edges and top/bottom termination points of the glass grid.

Glass Canopies: Used at the wall connection point where the canopy meets the building.

Atriums & Skylights: Connecting the perimeter glass panels to the main support ring.

Storefronts: Heavy-duty support for tall retail glass frontages.

Frequently Asked Questions (FAQ)

Q: What is the difference between a 3-Way and a 4-Way spider?

A: A [4-Way Spider] is X-shaped and used in the middle of a glass wall where four panels meet. A 3-Way Spider is typically T-shaped and used at the edges where only two panels meet, or where the grid ends.

Q: Can this 160mm spider support double-glazed units (DGU)?

A: Yes, the 160mm spider is strong enough for insulated glass units. However, you must ensure you purchase [longer articulated routels] designed specifically for double glazing to fit through the thicker glass makeup.

Q: Do you stock the "Y-Shape" 3-way spiders?

A: The standard for the 160mm series is the "T-Shape" (90-degree and 180-degree angles). However, we can manufacture "Y-Shape" (120-degree angles) for specific radial or curved projects upon request. Please contact our sales team for custom casting.

Q: How do I clean the fittings after installation?

A: To remove construction dust and fingerprints, simply use warm water with a mild soap and a soft microfiber cloth. Never use acid-based cleaners or hydrochloric acid on stainless steel, as this will damage the protective layer and cause rust.

Why Buy From Stainless Steel Hardwares?

Factory Direct: No middlemen implies better pricing for your project.

Global Shipping: We export to the USA, Europe, Australia, and the Middle East regularly.

Technical Support: We don't just sell parts; we understand the system. We can help you check your drawings to ensure the 160mm 3-way fitting is the right choice for your load requirements.

Ready to order?